ceramics interpreted with new formats and

applications for piece-by-piece installation

ceramics interpreted with new formats and

applications for piece-by-piece installation

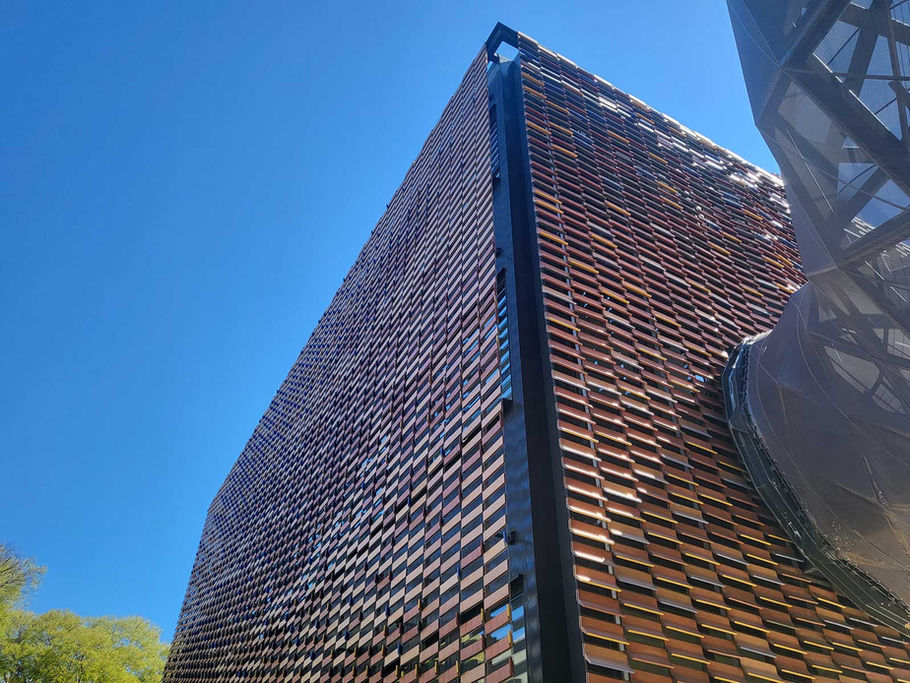

What is a ceramic fabric?

It is a system of large-format components engineered from small-format ones that supports the application of modern construction technologies for ventilated facades and pre-industrialized trusses, providing the building's "skin" with enhanced bioclimatic protection and giving it unique effects of transparency, color, brightness, and texture.

Today we no longer have modernist craftsmen, but we do have a construction technology capable of reproducing facades that hark back to the historical architecture of contemporary times.

A new construction system with high added value: multiple applications, a new architectural language, the possibility of using other materials, colors...

This paper aims to present the advantages of integrating ceramic fabrics into contemporary facades, with a highly technological and advanced material originating directly from a materiality and related to that of a traditional material such as ceramic, but not limited to it.

Ventilated air chamber

The ceramic in the building envelope reduces the heat effect, decreasing the internal ambient temperature.

This sunshade creates a shade that protects the internal functional facade from solar radiation, particularly important in the case of metal or glass facades.

Rear ventilation adds a significant improvement in thermal insulation by expelling accumulated heat from the summer sun, resulting in energy savings for cooling or heating the building.

The advantages of the Ceramic Fabric System

Sustainable architecture

The ceramic fabric building incorporates the most demanding contemporary parameters in terms of sustainability and circular economy. We have success stories with buildings that, by implementing the system with the appropriate solutions for the building envelope, have achieved excellent results with maximum energy savings, high energy certification, and minimal environmental impact, including LEED Platinum environmental certification, in which cases the use of the system has been decisive in achieving these goals.

Industrialization

The industrialization of the system allows costs to be minimized with high performance, as large-format sheets can be produced in a single operation, minimizing the energy and labor required for installation.

Circular economy

This results in demountable buildings, composed of components manufactured in the workshop and assembled on site, instead of the traditional construction system. This allows for quality control, minimizes waste and energy consumption, and increases safety by allowing components to be dismantled when necessary instead of demolished, with recycling that revalues materials in line with the dynamics of the circular economy.

Flexibility

It is a convertible facade. The flexibility to adapt to future changes in use is almost total. It can be adapted to new configurations simply by repositioning parts, removing or adding some, or even changing their materiality. Ensuring that it can be completely reformed in the future substantially extends the potential life of the element.

Protection from solar radiation

It reduces energy consumption thanks to its bioclimatic architecture. It combines good protection from solar radiation, improving the quality of the functional layer of the facade and providing excellent insulation, especially when aided by high internal thermal loads and the inertia of the materials. This allows the building to require less energy for comfort.

Reduces the impact of materials

It introduces the use of materials with low environmental, economic, and maintenance impact, compared to materials such as aluminum or natural stone. Lightweight construction elements have also been prioritized over heavy ones, which implies a lower impact of transport in terms of CO2, energy, and costs.

Reduced maintenance requirements

The reduced maintenance requirements of ceramic and stainless steel parts minimize the use of water and cleaning chemicals, resulting in reduced use of chemical contaminants and energy.

Healthy facade

Ceramic fabric is composed of materials with minimal volatile organic compounds (VOCs), thus reducing indoor air pollutants.

Jali effect

The lattice or jali arrangement of ceramic fabrics helps reduce the temperature by compressing the air through the holes. In addition, when air passes through these openings, its speed increases, providing deep air diffusion. It is a traditional element commonly used in architecture in India and Islamic countries, where it has proven its effectiveness for this purpose.

ADVANTAGES:

Industrialized production

Positioning speed

Easy and simple to position

It facilitates the repair of the pathology

Few operators

Removable, recoverable

Multiple color finishes

Reliability of the final appearance

Free joints

Free dilation

Construction versatility

Flexible, adaptable

Multiple color finishes